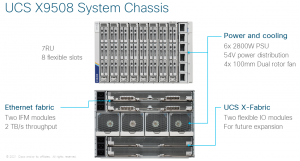

The Cisco UCS X-Series begins with the Cisco UCS X9508 Chassis. Our engineering teams rethought everything: modularity, size, power, cooling, and fabrics. The result is a great infrastructure choice to base your hybrid cloud computing platform on for the next decade.

Modularity

Modularity is key to flexibility and future-proofing. Since the chassis has no midplane or fixed connections, every component can be replaced without requiring a forklift upgrade. The chassis can be upgraded by simply installing new nodes; from PCIe Gen 4 to PCIe Gen 5 for example. This means that your initial investment will live longer, increasing your ROI.

Size

12 years ago, our 6RU blade chassis had enough space to power, cool, and provide Unified Fabric connectivity for eight servers. The new UCS X9508 chassis still has eight slots, but times have changed. These slots will hold compute nodes and non-compute nodes in the future. Server subsystems (CPU, memory, GPU, etc.) demands have grown as performance and capabilities have increased. The X9508 chassis has grown 1RU and is a 7RU chassis to accommodate them. I know it sounds like weird math, but that small change provides a 27% increase in interior space vs. our previous chassis. This is accomplished with the removal of the IO midplane, the horizontal orientation of the fabric, and the vertical orientation of the blades and power supplies. This prepares us for the future of higher-performing CPUs and interconnects more memory and more accelerators like GPUs.

Power

There are six, 2800W, Titanium rated, power supplies. Almost a 50% increase over our previous chassis. Why the huge leap? The component demands have increased. When UCS launched 12 years, CPUs required less than 100W. Today, they can require almost 300W. And in the future…

That’s not the only change. The X9508 chassis uses 54-volt power distribution. Why the change from 12-volt? Using 54-volt allows us to distribute more power using significantly less current. Less current means less waste heat. Both extend the life of the chassis. It also shrinks the space needed for power distribution (part of that 27% increase in interior space mentioned above).

Cooling

The X9508 Chassis has more than 2x additional cooling capacity to ensure future needs can be met. There are four main fans that are 100mm. These larger fans can run at lower speeds which reduces both noise and power consumption. There are also three 40mm fans within each Intelligent Fabric Module and forthcoming X-Fabric modules (more on these in a future blog). The chassis’ total airflow is 1,000 CFM.

But the cooling improvements don’t end there. We’ve implemented both horizontal & vertical cooling zones that include the air and component temperature. This allows for independent fan speed control based upon the zone’s temperature and component’s power consumption. This improves efficiency, helps reduce noise, and the fan’s power consumption. These are all based on different fan speed control policies. You can bias toward acoustics or performance. All policies can be changed programmatically and non-disruptively.

Lastly, the chassis is a midplane-free design. This open concept ensures maximum airflow with the least impedance.

Fabric

One of UCS’ biggest benefits has always been Unified Fabric. That is carrying data, storage, and management traffic over a single wire. The X9508 uses the IFM (Intelligent Fabric Module) to deliver Unified Fabric to each compute node.

What is Cisco UCS X-Fabric Technology? In math, X is a classic variable. Here, it is a variable fabric for the chassis and nodes. It will allow us to add additional capabilities without having to rip and replace the existing X9508 chassis.

Source: blogs.cisco.com Credit@ Bill Shields